Engineering precision, solving complexity, delivering innovation across every frontier.

From intelligent subsea flow control and modular vessel handling systems to off-grid renewables and aerospace cargo solutions, our case studies reflect the breadth of challenges we solve. Each project demonstrates how we deliver tailored, high-performance engineering — whether it’s controlling pressure, managing motion, enabling autonomy, or integrating complex systems in unforgiving environments.

Project: Subsea Compression Upgrade

Sector: Oil & Gas

Challenge:

Aging subsea infrastructure required capacity expansion to maintain flow rates. Traditional solutions posed risk to uptime and CAPEX targets.

Our Approach:

We conducted a full FEED assessment and multi-discipline design for retrofitting high-efficiency subsea compressors into existing manifolds.

Solutions Delivered:

Mechanical & thermal redesign of compression module

Finite Element Analysis (FEA) for structural validation

CFD to model flow turbulence under reconfigured geometry

Materials engineering to meet corrosion and pressure specs

Outcomes:

Increased throughput by 18%

Installed with zero NPT

Full compliance with DNV and API 17D

Key Stats:

+18% Flow Capacity · 0 Days NPT · 25-Year Fatigue Life Verified

Case Study: Intelligent Flow Control System for HPHT Field

Sector: Oil & Gas – Upstream Production

Project: Multi-zone production optimization in a high-pressure, high-temperature (HPHT) offshore reservoir

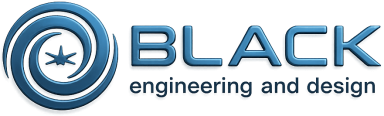

Case Study: Modular Deck Handling System for Pipe & Mattress Deployment

Sector: Maritime – Offshore Construction Support

Project: Design of a multi-function back deck handling system for pipe laying and subsea mattress deployment on a fleet of converted supply vessels

Case Study: Back Deck Tubular handling system.

Sector: Maritime

Telescopic A-frame with 45° outreach and 25t SWL. Interchangeable handling heads

Full FEA and fatigue analysis for 15-year design life. DNV approval documentation package + site installation supervision

Case Study: The client required a reconfigurable cargo bay system to increase load/unload efficiency during high-tempo operations. Existing net-and-pallet solutions were:

Slow to reconfigure between missions

Prone to human error in lashing/strapping

Not optimized for modern cargo diversity (mixed pallets, containers, mission kits)

Requirements included:

Compatibility with NATO-standard tie-down points

Non-electric, tool-free assembly

Survivability under 9g deceleration

Case Study: The client needed a clean, silent, and maintenance-light power solution for vehicle-mounted, mobile structures operating in remote terrain for up to 12 months. The goal was to:

Eliminate diesel reliance

Support sensitive electronics and lighting

Survive extreme weather and rough transport

Be expandable across 3–5 vehicle base layouts

INNOVATIVE DESIGN SOLUTIONS

Together, we move forward — united in purpose, driven by curiosity, shaping a brighter world where every challenge becomes a chance to build something extraordinary.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.